When you're hauling cars, less-than-truckload (LTL) freight, or other medium-duty loads with a Class 3 to Class 6 truck, choosing the right gooseneck hitch is critical. It’s not just about towing capacity—it’s about reliability, ease of use, and ensuring your setup matches your operational needs. You'll have to choose between two options: bolt-on vs weld-on gooseneck hitches. Each has distinct advantages and trade-offs, and understanding these can help you make an informed decision that keeps your business running smoothly.

In this guide, we’ll break down what we think are the most important differences between bolt-on and weld-on gooseneck hitches, focusing on their installation, durability, flexibility, and suitability for commercial haulers. Whether you're an experienced driver researching upgrades or a newbie sourcing equipment, this post will help you choose the hitch that’s right for your towing rig. To summarize what we're about to say:

Bolt-on hitches offer easy installation and removability, making them ideal for leased or multi-use trucks. Weld-on hitches deliver greater strength and long-term reliability, making them best for dedicated heavy-duty towing.

Start With the Right Gooseneck Hardware

-

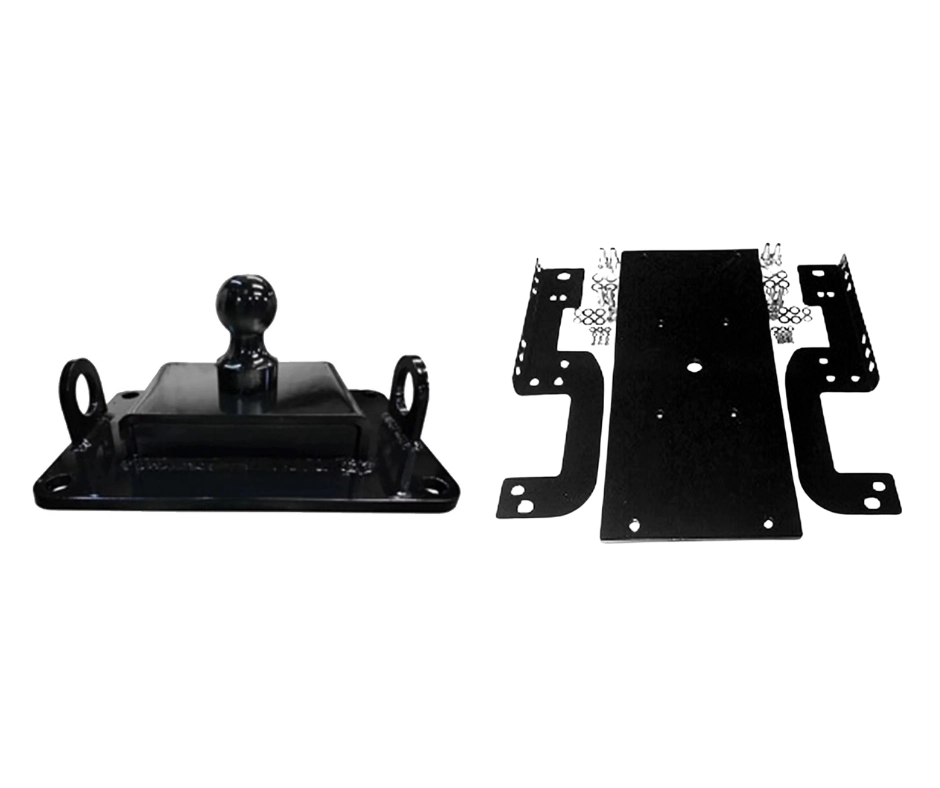

Gooseneck Kit With Bolt On Mounting Plate

Price range: $740.00 through $815.00 -

Gooseneck Bolt-on Ball Plate

Price range: $225.00 through $300.00 -

Receiver & Pintle Combo Hitches

$500.00

What Are Gooseneck Hitches?

Before diving into the bolt-on vs. weld-on debate, let’s clarify what a gooseneck hitch is for the new guys. Unlike a traditional fifth-wheel hitch, a gooseneck hitch uses a ball-and-coupler system mounted in the truck bed, directly above the rear axle. This design provides superior stability and weight distribution, making it ideal for towing heavy loads like car trailers, flatbeds, or LTL cargo with Class 3 (e.g., Ford F-350), Class 4 (e.g., Ram 4500), Class 5 (e.g., Chevy Silverado 5500HD), or Class 6 (e.g., International CV) trucks.

Both bolt-on and weld-on gooseneck hitches are secured to mounting brackets under the truck bed and can be removed by detaching four bolts, offering flexibility when the hitch isn’t in use.

The key difference lies in how these mounting brackets are attached to the truck’s frame—bolted or welded—which impacts installation, durability, and long-term use.

Bolt-On Gooseneck Hitches: Flexibility and Convenience

How They Work

Bolt-on gooseneck hitches are attached to the truck’s frame using factory-drilled mounting holes or custom-drilled holes that align with the hitch’s brackets. High-strength bolts secure the brackets, and the hitch itself is mounted on top, typically with a ball that can be flipped or removed when not in use.

Advantages

- Ease of Installation: Bolt-on hitches are a dream for those who want a straightforward setup. Most installations can be completed in a few hours with basic tools, especially if your truck has pre-existing mounting holes. No welding expertise or specialized equipment is required.

- Removability: Need to switch between towing and non-towing setups? Bolt-on hitches are designed for easy removal. Unbolt the hitch and brackets, and your truck bed is free for other tasks.

- No Permanent Alteration: Since bolt-on hitches don’t require welding, they preserve your truck’s frame integrity. This is a big plus if you lease your vehicles or plan to resell them later.

- Cost-Effective: Bolt-on hitches typically have lower installation costs, as they don’t require professional welding services.

Drawbacks

- Slightly Less Strength: While bolt-on hitches are robust (often rated for 25,000–30,000 lbs. gross trailer weight), they may not match the sheer durability of a welded connection, especially under constant heavy-duty use.

- Potential for Loosening: Bolts can loosen over time due to vibration or extreme loads, requiring regular inspections and maintenance to ensure a secure connection.

- Fitment Issues: Some trucks may require custom drilling or adapters, which can complicate installation if the factory holes don’t align perfectly.

Mounting Bolt on Plate Kit

$740.00 – $815.00

This bolt-on ball kit is designed for cab chassis trucks and includes both the gooseneck ball and the mounting plate, offering a complete solution for your towing setup. The kit is available in 2 5/16″ or 3″ sizes and mounts securely to your truck frame.

Bolt On Gooseneck Hitches Are Best For

Fleets With Versatile Needs

If your trucks switch between towing and other tasks, the removability of bolt-on hitches is a major advantage.

Leased or Resellable Trucks

Bolt-on hitches avoid permanent frame modifications, preserving vehicle value.

Smaller Operations

If you’re a small business or independent hauler without access to welding equipment, bolt-on hitches are easier to install and maintain.

Weld-On Gooseneck Hitches: Strength and Permanence

How They Work

Weld-on gooseneck hitches are permanently attached to the truck’s frame through professional welding. The mounting brackets are welded directly to the frame, and the hitch is bolted onto these brackets, allowing for removal of the hitch itself when not in use.

Advantages

- Unmatched Durability: Weld-on hitches provide a rock-solid connection that’s virtually impervious to vibration or loosening. This makes them ideal for frequent, heavy-duty towing.

- Higher Load Confidence: The welded connection can handle extreme loads with minimal risk of failure, offering peace of mind for haulers carrying valuable cargo like cars or LTL freight.

- Custom Fit: Weld-on hitches are tailored to your truck’s frame during installation, ensuring a perfect fit that maximizes strength and stability.

- Long-Term Reliability: Once welded, the brackets require little to no maintenance, reducing downtime and inspection costs.

Drawbacks

- Permanent Modification: Welding alters the truck’s frame, which can reduce resale value or violate lease agreements. It’s a long-term commitment to towing.

- Complex Installation: Welding requires specialized skills and equipment, meaning you’ll likely need to hire a professional. This increases upfront costs and installation time.

- Less Flexibility: While the hitch itself can be unbolted, the welded brackets remain, which may interfere with other truck bed uses.

Heavy-Duty Hardware for Dedicated Hauling

-

34K Haulin’ Head Unit

$895.00 -

50K Haulin’ Head Unit

$1,295.00 -

34K Haulin’ Head Unit With Bolt On Plate

$995.00

Weld On Gooseneck Hitches Are Best For

Dedicated Towing Fleets

If your trucks are primarily used for towing and rarely switch to other tasks, weld-on hitches offer unmatched reliability.

High-frequency Haulers

Drivers who tow heavy loads daily will benefit from the durability and low maintenance of weld-on hitches.

Long-term Ownership

If you own your trucks and plan to keep them for years, the permanent nature of weld-on hitches is less of a concern.

Key Considerations for Commercial Haulers

Choosing between bolt-on and weld-on gooseneck hitches depends on your operational priorities. Here are some questions to guide your decision:

- How often do you tow? If towing is occasional or your trucks serve multiple roles, a bolt-on hitch’s flexibility is ideal. For daily towing, a weld-on hitch’s durability shines.

- What’s your budget? Bolt-on hitches are generally cheaper to install, while weld-on hitches have higher upfront costs but lower long-term maintenance.

- Do you own or lease your trucks? Bolt-on hitches are better for leased or resellable trucks, as they avoid permanent frame modifications.

- What’s your towing capacity? Both hitch types can handle the 10,000–30,000 lbs. typical for Class 3–6 trucks, but weld-on hitches offer extra confidence for maxed-out loads.

- Do you have access to welding services? If not, bolt-on hitches are the practical choice.

Why Choose Hitch Crafter?

At Hitch Crafter, we understand the demands of commercial hauling. Our bolt-on and weld-on gooseneck hitches are engineered for Class 3 to Class 6 trucks, with towing capacities up to 30,000 lbs. and easy-to-use designs. Both hitch types feature removable balls and can be unbolted in minutes, giving you flexibility without sacrificing strength. Whether you need the convenience of a bolt-on hitch or the rugged durability of a weld-on model, our products are built to keep your business moving.

Final Thoughts

For light to medium commercial haulers, the choice between bolt-on and weld-on gooseneck hitches comes down to a balance of flexibility, durability, and cost. Bolt-on hitches are perfect for versatile fleets, leased trucks, or budget-conscious operations, offering easy installation and removability. Weld-on hitches, meanwhile, are the go-to for dedicated towing, heavy loads, and long-term reliability, provided you’re comfortable with permanent frame modifications.

Evaluate your towing frequency, truck ownership status, and budget to make the right call. And when you’re ready to equip your fleet, trust Hitch Crafter for hitches that deliver performance and peace of mind.

Ready to choose your hitch? Contact Hitch Crafter today for expert advice and top-quality gooseneck hitches tailored to your needs.

Contact Us

Let's make something special! Provide us with the vehicle information and a short description for what you're looking for. We'll contact you with some ideas to get started.

"*" indicates required fields